Professional expertise, design essence

Product Design and Development

Leveraging the experience of serving over 5,000,000 households, we deeply understand our customers' needs and continuously overcome technical challenges to design products that best fit their lives. Each new product launch is based on research from 60,000 real-life cases, with high-frequency and in-depth surveys to adapt to the rapidly changing market. With two design teams and countless brainstorming sessions, we work together to introduce 100% independently developed new products.

Selection of Raw Materials

Copper Material: After comparing 910 copper mines domestically, we chose high-purity copper materials produced from the Dexing Copper Mine in Jiangxi. Through six rounds of smelting and processing, we produce a 2.5mm thick Grade 59A copper body. Stainless Steel Material: We carefully select 0.9mm thick 304 stainless steel for use as shower components.

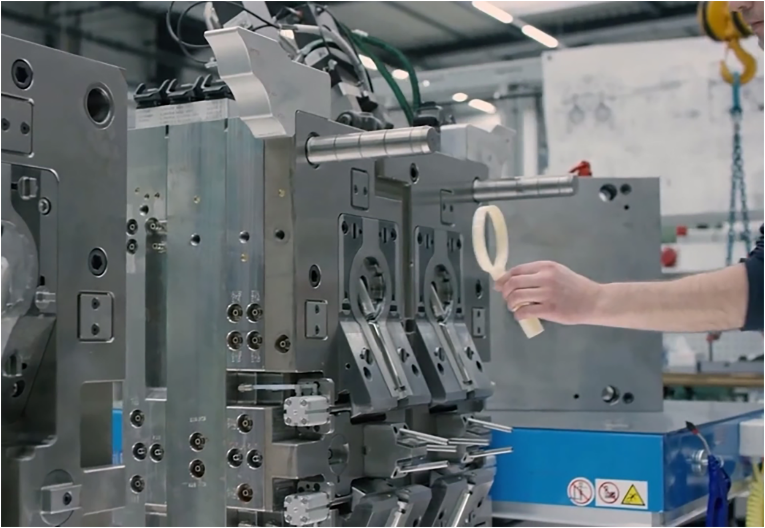

24 Processing Techniques

With 20 years of experience, we have switched from casting to precision stamping to produce high-precision and high-quality metal products. With the advancement of technology, we use CNC precision machining, cutting, grinding, drilling, milling, and other high-precision machines for raw material processing. All machined parts must undergo manual polishing to achieve a standard of 100% polishing per piece before undergoing color processing. We use environmentally friendly and durable surface treatment methods such as electroplating, wire drawing, and PVD oil sealing.